Understanding Acrylic Resins and Their Role in Modern Manufacturing

What Are Acrylic Resins and Why They Matter in Production

Acrylic resins come from acrylic acid derivatives and form the basis for all sorts of products including coatings, adhesives, and those really precise cast parts needed in specialized applications. What makes these thermoplastics stand out is their clear appearance combined with good chemical resistance, which explains why they show up so often in things like airplane molds, medical equipment, and car paint jobs. When it comes to practical benefits, acrylics resist UV damage pretty well and don't shrink much when cured, cutting down on wasted material after processing. Some industry tests suggest this can save around 20% compared to similar epoxies. For manufacturers looking to balance quality with efficiency, acrylic resins offer both strength and versatility that just keeps them relevant across various production settings.

Key Properties of Acrylic Resins Influencing Processing Efficiency

Three core properties define their value in production:

- Solvent Resistance: Minimizes warpage in high-humidity environments, reducing defect rates by 19% in injection molding

- Thermal Stability: Maintains dimensional accuracy (±0.05mm) at temperatures up to 160°C, crucial for heat-cured tooling

- Adhesion Versatility: Bonds reliably to metals, ceramics, and composites without plasma pretreatment

These traits enable faster cycle times and tighter tolerances, especially in multi-material assemblies requiring resilience under thermal or chemical stress.

Comparing Curing Methods: Heat-Cured vs. Self-Cured Acrylic Resins

Heat-Cured Acrylic Resins: Stability and Dimensional Accuracy in High-Volume Production

Heat-cured acrylic resins use controlled temperatures (100–150°C) to achieve cross-linking, ensuring <2% variation in mechanical properties across batches (thermal curing kinetics study, Nature 2021). Widely used in dental and automotive mass production, these systems deliver assembly-ready parts with shrinkage as low as 0.3–0.6%. Key advantages include:

- Consistent glass transition temperature (Tg): ±3°C repeatability

- Minimal post-processing: 92% of molded parts meet surface finish requirements out-of-mold

Self-Cured Acrylic Resins: Rapid Prototyping and Bedside Adjustments

Self-curing resins polymerize in 8–12 minutes at ambient conditions, eliminating the need for ovens or external energy sources. As shown in analyses of industrial curing systems, this method reduces energy costs by 40%, though higher shrinkage (1.8–2.1%) demands design compensation:

| Property | Heat-Cured | Self-Cured |

|---|---|---|

| Cure Time | 45–90 minutes | 8–12 minutes |

| Shrinkage | 0.3–0.6% | 1.2–2.1% |

| Typical Application | Mass production | Prototyping/Repair |

Shrinkage Rates and Final Product Integrity: A Critical Comparison

Dimensional stability is directly linked to cross-linking density—heat-cured resins achieve 85–90% conversion versus 70–75% in self-cured variants. While self-cured materials support real-time adjustments in medical fittings, their threefold higher shrinkage leads to secondary machining in 68% of cases, extending project timelines by 15–20%.

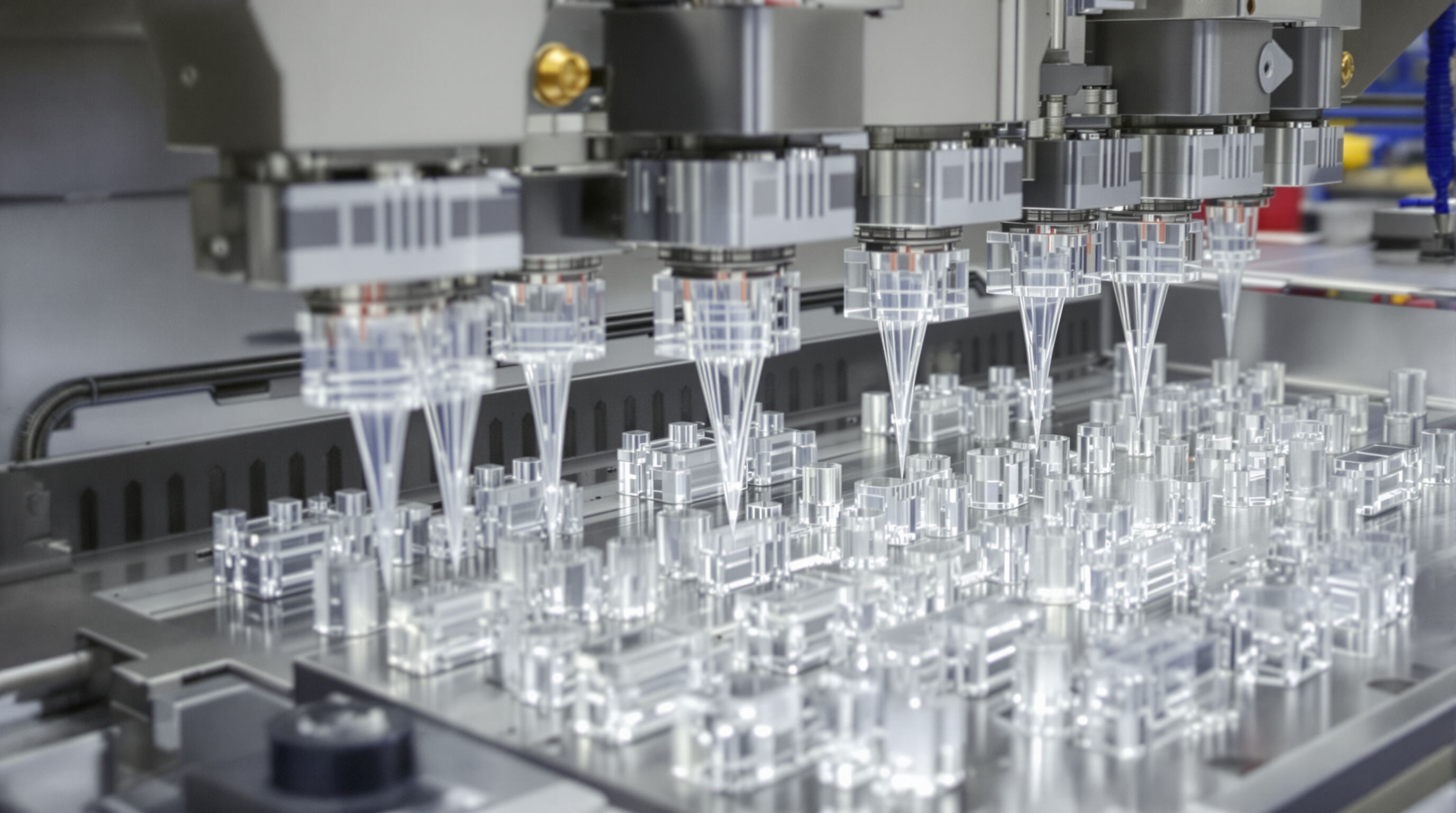

Injection Molding with Acrylic Resins: Enhancing Precision and Scalability

Optimizing Mold Design to Minimize Warpage and Defects

Good mold design really helps control those annoying thermal stresses that come with working with acrylic materials. When cooling channels are laid out evenly across the mold, this can cut down on temperature differences by around 18 to 22 degrees Celsius per millimeter according to recent research from Material Science Journal in 2023. This makes a big difference in reducing leftover stress and preventing warping issues. Using conformal cooling systems along with quality steel molds improves how heat moves away from the part, which means fewer size variations overall something manufacturers love seeing since it drops problems by about 40%. And let's not forget flow simulation tools these days. They're fantastic at spotting where air gets trapped in complicated shapes, so engineers can optimize vents properly. This simple step alone reduces defects by roughly 15 to 20%, making production runs much smoother.

Processing Parameters That Improve Surface Finish Quality

Getting the right melt temperature between 220 and 260 degrees Celsius along with proper injection pressure around 80 to 120 MPa makes all the difference when it comes to achieving good optical clarity. The injection speed should stay within 0.5 to 1.5 millimeters per second to avoid those pesky flow lines. Keeping the mold temperature somewhere between 25 and 30 degrees Celsius helps minimize sink marks as well. When manufacturers implement dynamic pressure profiling they can actually control viscosity variations by about plus or minus 2 percent during the filling process. This results in much smoother surfaces too, reducing roughness values from approximately 1.2 micrometers down to just 0.4 micrometers on transparent parts.

Case Study: Achieving 30% Cycle Time Reduction Through Temperature Control

One medical device company recently installed real-time mold temperature sensors to keep cavity temperatures within about 1 degree Celsius of each other. This change cut down on cooling times significantly, bringing them down from around 22 seconds to just 15 seconds per cycle. When paired with better control over the barrel temperature stability, these improvements shaved off nearly 30% from the overall cycle time without compromising quality standards set by ASTM D638 for tensile strength testing. What does this mean in practice? The production line can now churn out approximately 12 thousand units every day with rejection rates below half a percent, which is pretty impressive when considering what they were dealing with before making these adjustments.

Digital Fabrication Techniques: CAD/CAM and Milling for Acrylic Resins

CAD/CAM vs. Conventional Methods in Denture Base Manufacturing

Most dental labs have moved away from traditional hand techniques when making acrylic resin dentures, opting instead for CAD/CAM systems. According to recent studies published in BMC Oral Health last year, these computer-aided processes create denture bases with margins that deviate only about 0.05 millimeters on average. That's roughly 40 percent improvement over old school methods, plus it saves around 23% of the total production time needed. The software automatically creates paths for tools to follow, which basically removes those pesky mistakes people sometimes make during wax modeling or flasking steps. This leads to much more consistent results across different cases and ultimately better fitting dentures for patients.

Tool Selection and Its Impact on Surface Roughness in Milling

Carbide end mills with ⌀ 0.5 mm diameter yield surface roughness (Ra) below 2.1 μm—ideal for mucosal contact surfaces. Operating at spindle speeds of 18,000–25,000 RPM minimizes heat buildup and surface cracking while maintaining ±0.1 mm tolerance.

AI-Driven Path Planning: Emerging Trends in Digital Machining

Machine learning algorithms now optimize milling paths by analyzing resin behavior and exothermic reactions. These systems reduce non-cutting time by 15% and predict tool wear with 92% accuracy, enabling uninterrupted 8-hour production runs.

Balancing High Accuracy and Material Waste in Digital Workflows

Nesting algorithms in CAD/CAM software reduce material waste from 35% to 12% through intelligent 3D part arrangement. Adaptive toolpaths focus precision on functional surfaces, preserving tight tolerances (<50 μm) while incorporating recycled acrylic chips for non-load-bearing components.

Additive Manufacturing: 3D Printing Acrylic Resins for Advanced Applications

Resin Formulation Requirements for Stereolithography (SLA) Compatibility

For SLA printing, acrylic resins need to have a viscosity range somewhere around 500 to 2000 centipoise, and they should react properly to ultraviolet light in the 355 to 405 nanometer wavelength range. A recent paper from the Annals of 3D Printed Medicine back in 2022 found something interesting too. When formulas contain less than 25 percent monomer content, they actually cut down on curing stress by about 34 percent. That's pretty significant. Dentists and lab technicians especially look for low shrinkage materials these days. These special resins only shrink about 0.6 percent or less when cured, which makes them ideal for things like dental crowns and those tiny fluid control systems where even minor dimensional changes can cause problems.

Post-Processing Challenges: Reducing Surface Roughness in Printed Parts

IPA washing reduces surface roughness (Ra) from 8.2 μm to 3.5 μm in biocompatible dental appliances. However, over-curing compromises mechanical performance—12 minutes of UV exposure optimally balances tensile strength (58 MPa) and elongation (8%). For optical applications, centrifugal polishing achieves Ra ⌀ 0.8 μm but adds 22–35 minutes per part.

Hybrid Workflows: Combining 3D Printing and Milling for Superior Finish

When combining SLA printing with 5-axis CNC milling, manufacturers typically see around a 40% reduction in post-processing time, plus they get pretty good positional accuracy under 10 microns. The process works by letting 3D printing handle those complex shapes that would be tough to mill directly, while reserving the CNC for areas needing tight tolerances. For things like facial implants, this combo has cut down on adjustment time by almost two-thirds according to recent studies. The machine adapts its cutting path as it goes along, keeping all those fine printed details intact while taking off just enough material (about half a millimeter) to finish the part properly. This saves both time and money in production shops working on medical devices.

FAQ

What are the main uses of acrylic resins in manufacturing?

Acrylic resins are widely used for coatings, adhesives, and precision cast parts. They are popular in the manufacture of airplane molds, medical equipment, and car paint due to their clarity and chemical resistance.

How do heat-cured and self-cured acrylic resins differ?

Heat-cured resins require controlled temperatures to achieve cross-linking, ensuring low shrinkage and consistency. Self-cured resins polymerize quickly at ambient conditions, reducing energy costs but generally resulting in higher shrinkage.

What is the advantage of using injection molding with acrylic resins?

Injection molding with acrylic resins allows for precision and scalability. Good mold design minimizes warpage and defects, while optimized processing parameters ensure excellent surface finish quality.

Can acrylic resins be used in 3D printing?

Yes, acrylic resins can be used in 3D printing. They are compatible with SLA technology when they meet certain formulation requirements, ensuring low shrinkage and high precision for intricate designs.

How do CAD/CAM systems benefit dental acrylic resin manufacturing?

CAD/CAM systems improve consistency and reduce production time in dental manufacturing. They automatically create precise toolpaths, reducing errors and enhancing the fit and quality of dental appliances.