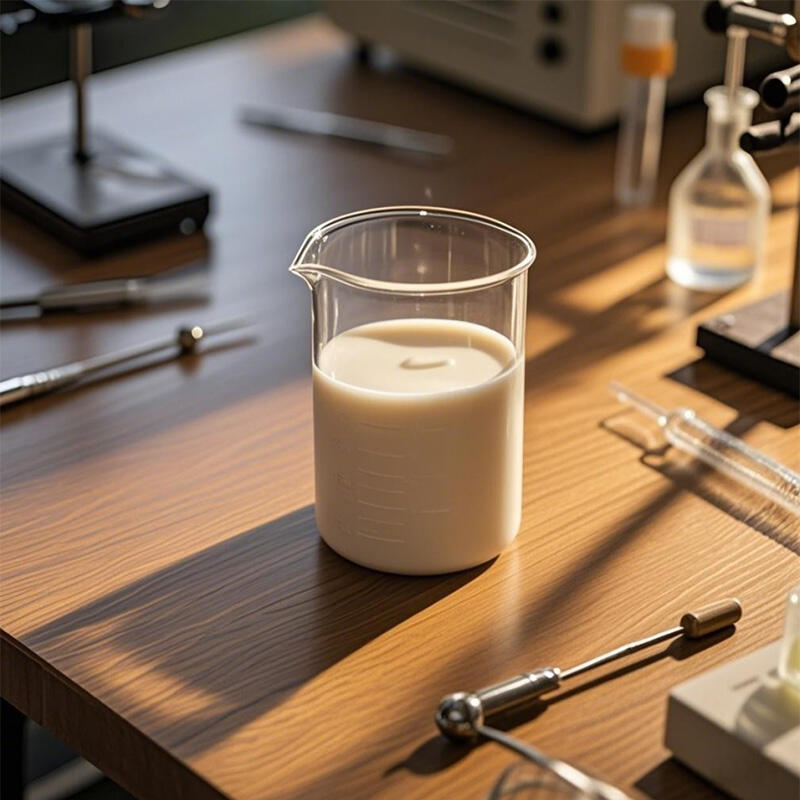

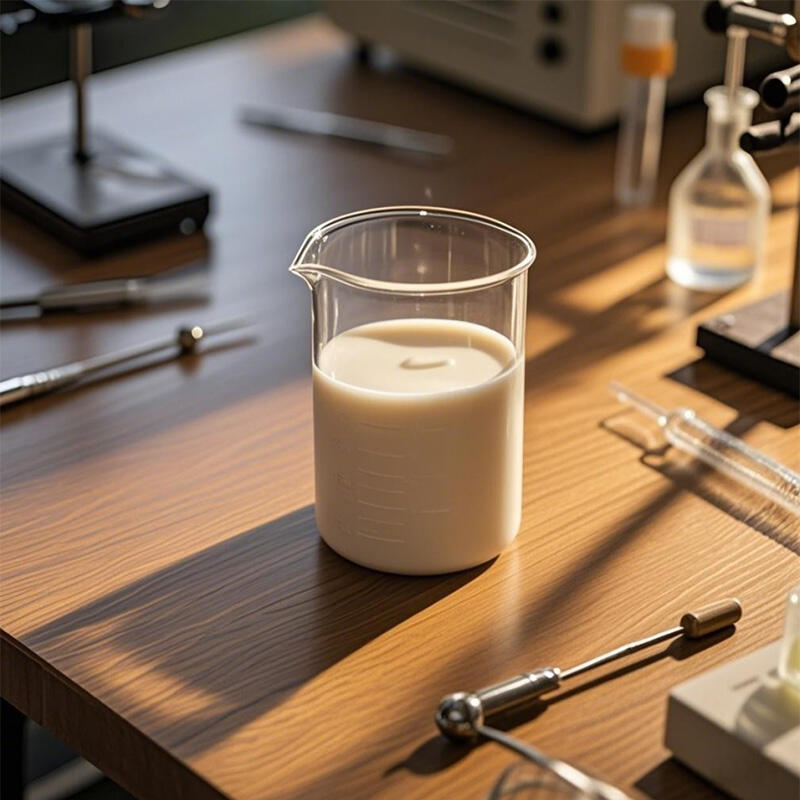

This adhesive is a water-based resin emulsion polymerized from acrylic monomers, with water serving as the dispersion medium. It is environmentally friendly, featuring low VOC levels, and is known for its excellent film-forming properties. The adhesive is suitable for use in coatings, adhesives, and various other fields. Proper storage is required to prevent exposure to freezing temperatures and high heat, and precautions should be taken to avoid spills.

Water-Based Acrylic Resin Emulsion Adhesive

Composition & Technology:

This adhesive is formulated as an advanced aqueous emulsion synthesized through free-radical polymerization of acrylic monomers (e.g., 2-Ethylhexyl Acrylate, butyl acrylate, methyl methacrylate). Water acts as the primary dispersion medium, creating a colloidal system where polymer particles (typically 50–500 nm in size) are uniformly suspended. This design eliminates the need for volatile organic solvents (VOCs), aligning with global sustainability mandates.

Key Advantages & Environmental Profile:

Eco-Compliance & Safety:

Ultra-Low VOC (<50 g/L), reducing workplace hazards and environmental impact.

Non-flammable, non-toxic during application, and compliant with regulations (e.g., REACH, LEED).

Easily cleaned with water, minimizing hazardous waste disposal costs.

Superior Film-Forming Performance:

Forms continuous, high-clarity films at ambient temperatures via particle coalescence.

Delivers exceptional adhesion-to-substrate wetting on diverse surfaces (plastics, metals, treated woods).

Exhibits balanced elasticity-toughness for dynamic stress resistance (peel, shear, flexion).

Stability & Compatibility:

Resists hydrolysis and viscosity drift via optimized surfactant/pH systems.

Compatible with additives (thickeners, defoamers, crosslinkers) for property enhancement.

Critical Storage & Handling Protocols:

Temperature Control: Maintain between 5°C–30°C (41°F–86°F).

Freezing Risk: Below 0°C (32°F) causes irreversible particle coalescence → gelling/loss of functionality.

Heat Exposure: >40°C (104°F) accelerates bacterial growth/viscosity drop → phase separation.

Container Management:

Use corrosion-resistant sealed containers (HDPE/stainless steel).

Prevent skinning by blanketing with nitrogen if stored >30 days.

Spill Mitigation:

Contain leaks with absorbent polymers (e.g., polyacrylate spill kits).

Avoid drainage contamination – neutralize pH before disposal.

Performance-Enhancing Customization:

Crosslinking: Post-addition of aziridines or carbodiimides boosts chemical/creep resistance.

Coalescents: Ethylene glycol ethers optimize film formation in low-temperature environments.

Biocides: Isothiazolinones ensure microbial stability in humid applications.

| Solid Content |

54.5% (±0.5%) |

Viscosity |

<100mpa.s |

PH |

6.5-8.5 |

Weight |

±0.3% |

| Appearance |

Milky white fluid |

| Functional Monomers |

Contains functional monomers such as AA to enhance crosslinking properties |

| Low VOC |

Environmentally friendly with no solvent odor |

● Eco-friendly: Low VOC emissions make it suitable for environmentally conscious applications.

● Versatile: Excellent film-forming capabilities allow for use in a wide range of products.

● Enhanced Performance: Functional monomers improve crosslinking, enhancing the adhesive's performance and durability.

● Adhesive Industry: Ideal for manufacturing tapes, labels, and other pressure-sensitive adhesive products.

● Leather and Textile: Suitable for use as a finishing agent to improve the quality and durability of leather and textile products.

● Additives: Can be used in various formulations to enhance product performance in different industrial applications.

Q:What makes this adhesive environmentally friendly?

A:The adhesive is formulated with low VOC emissions and water as the dispersion medium, making it an eco-friendly option.

Q:What are the storage requirements for this adhesive?

A:It should be stored in conditions that avoid freezing temperatures and high heat to maintain product integrity.

Q:Can this adhesive be used in outdoor applications?

A:Yes, its excellent film-forming capabilities and enhanced crosslinking properties make it suitable for various environments, including outdoor applications.

Q:How does the presence of functional monomers benefit the adhesive?

A:Functional monomers enhance crosslinking, resulting in improved performance and durability of the adhesive.