The coatings business worldwide is changing fast when it comes to being green, and acrylic emulsions are playing a big role in this transition. According to BCC Research from last year, these polymer dispersions already make up around 62% of all water based coatings, taking over from older solvent systems that release those harmful VOCs into the air. What makes acrylics so attractive? They're much better for the environment without sacrificing quality, which explains why so many manufacturers need them to meet rules like the EU's Directive 2004/42/EC. Looking specifically at architectural coatings, which remains the biggest market segment, nearly 6 out of 10 new interior and exterior paints now contain acrylic emulsions. This allows painters to get their work done quickly since drying times stay below two hours, all while keeping VOC emissions almost non-existent.

The water-based acrylic market is booming right now, hitting around $74.8 billion and growing at about 5.1% per year. This growth isn't just random either it's happening because companies worldwide need to follow stricter environmental regulations. When we look at these water-based options compared to traditional solvent-based products, there's a massive difference in VOC emissions reduction roughly 94%. And here's what's interesting they still manage to achieve similar hardness levels (around 2H to 3H on the pencil scale) plus impressive weather resistance that holds up for over 2,000 hours in salt spray tests. The auto industry has really caught on to this fast drying property. A recent study from the 2024 Automotive Finishes Report shows that manufacturers use waterborne acrylics for about 90% of original equipment manufacturer coatings, finishing them in less than 45 minutes. This speed boost actually helps factories crank out vehicles faster, with some reporting production line improvements of around 22%.

Three key forces are accelerating the adoption of acrylic emulsions:

The construction sector drives 39.1% of demand (Future Market Insights 2024), especially for fire-retardant acrylic emulsions meeting BS 476-7 safety standards. With the global sustainable coatings market projected to reach $87.8 billion by 2029, companies investing in acrylic emulsion R&D are positioned to capture 68% of new opportunities in eco-friendly protective finishes.

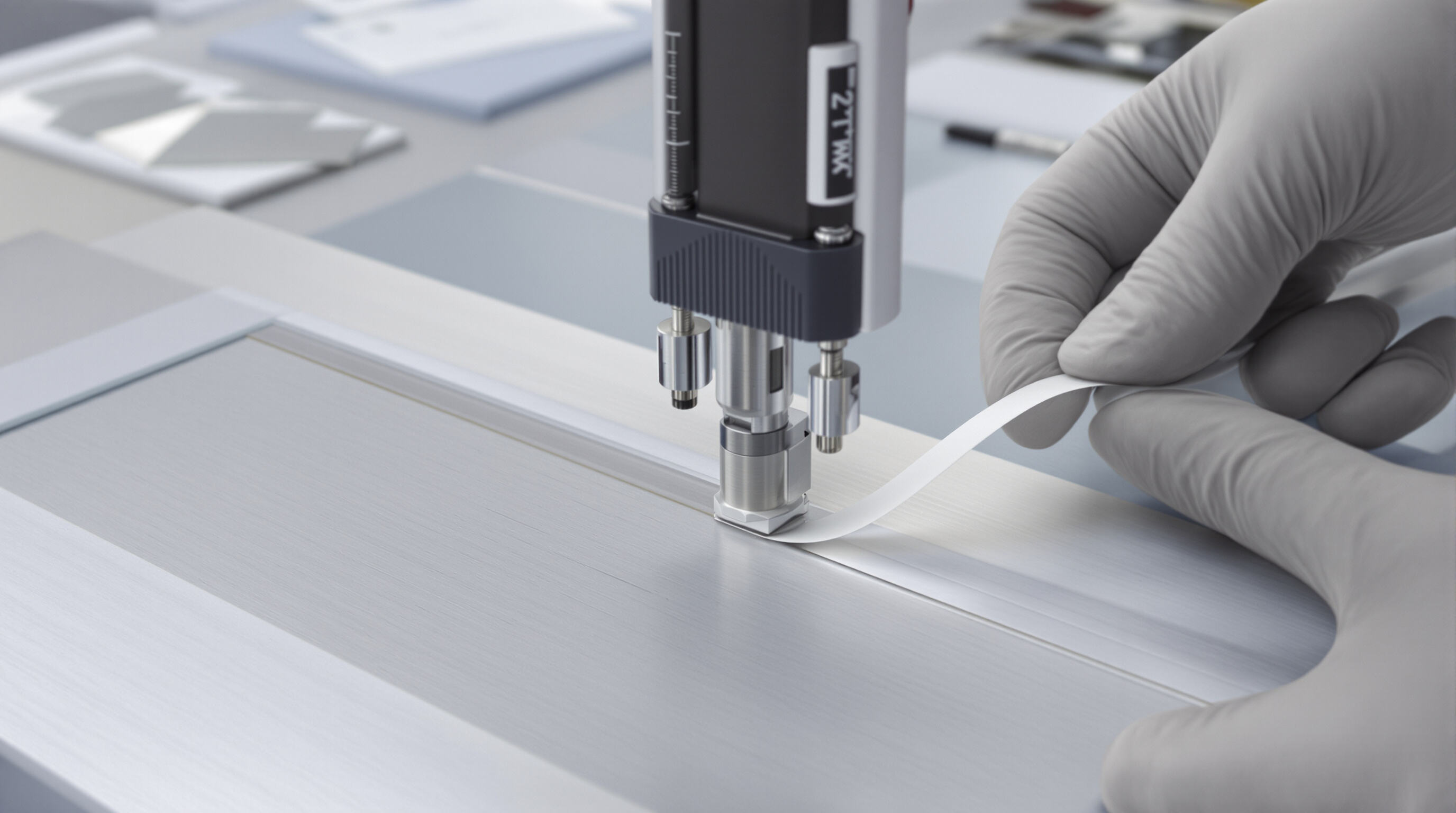

There are basically two main methods used in modern acrylic emulsion synthesis today. The first approach is called emulsion polymerization where particles form inside these little surfactant stabilized micelles. This process typically produces particles ranging from around 80 to 500 nanometers in size with solid content between 45% and 60%. These characteristics make them well suited for regular architectural coatings most of the time. On the other hand we have mini-emulsion polymerization which works differently. It relies on high shear homogenization techniques to generate much smaller particles under 100 nanometers with tighter size distribution ranges. What makes this method stand out is how much faster it forms films compared to traditional methods about 30% quicker actually. That speed advantage has made it especially popular among manufacturers needing those tough UV resistant coatings for cars and similar applications where durability matters most.

The latest acrylic emulsions feature what's called core-shell structures. Basically, these consist of a hard inner part made from materials like styrene-acrylic, wrapped up in a softer outer layer typically composed of butyl acrylate. This particular design makes them much better at resisting blocking issues, with some formulations showing around a 40 percent improvement in performance. They also handle those tricky Mandrel bend tests pretty well, often clearing the requirements even when the radius is below 3 millimeters. To get this kind of structure right, manufacturers need to carefully control how they feed different monomers into the system during the early stages of polymerization. Getting the timing and ratios just right is critical for achieving the desired properties in the final product.

Incorporating 2–5% functional monomers significantly boosts performance:

| Property Improvement | Functional Monomer | Typical Concentration |

|---|---|---|

| Adhesion Promotion | Phosphoethyl methacrylate | 1.5–3% |

| Crosslinking Density | Diacetone acrylamide | 2–4% |

| Hydrolytic Stability | Silane-modified acrylates | 1–2% |

An industrial trial demonstrated that silane-modified formulations reduced water absorption from 89 g/m² to just 3 g/m², dramatically improving moisture resistance.

Scaling acrylic emulsion production faces three primary challenges: maintaining particle size distribution within ±10% of lab results, ensuring viscosity consistency (under 200 cP variance), and preventing colloidal instability in large-scale (10,000-liter) batches. Continuous flow reactors are proving effective, cutting scale-up time from 18 months to just six for new formulations.

Water based acrylic emulsions get their durability from either self crosslinking mechanisms or by adding external crosslinkers. When materials self crosslink, they actually form those strong chemical bonds right as the film starts to develop, which makes things easier for whoever's applying them. On the other hand, stuff like aziridine compounds or carbodiimides work differently. These need to be added after application and then go on to create these network structures later on. Some recent research published in polymer science journals back in 2024 showed something interesting too. The studies indicated that when these reversible crosslinks happen naturally in self crosslinking systems, products end up being about 28 percent better at resisting cracks than what we see with conventional approaches. That kind of improvement really matters for coatings and paints where long term performance is critical.

Blending acrylic emulsions with inorganic or organic components overcomes material limitations. Silica hybrids increase hardness up to 3H without brittleness, while polyurethane-acrylic hybrids enhance chemical resistance. Research on hybrid dispersions showed a 42% improvement in salt-spray resistance in automotive coatings using 25–30% silica nanoparticles versus pure acrylic systems.

Researchers have been experimenting with incorporating zinc oxide and titanium dioxide nanoparticles, sized between 10 to 50 nanometers, into acrylic polymer materials to boost their performance when exposed to outdoor conditions. Recent tests conducted in 2023 showed promising results where acrylic films containing just 5% zinc oxide nanoparticles managed to absorb 90% of harmful UV rays while maintaining under 10% haze levels, which makes them pretty good candidates for clear architectural coatings. When put through rigorous QUV testing for an impressive 3,000 hours straight, these modified materials exhibited about 40% less yellowing than traditional UV protection solutions on the market today.

Optimal crosslinking density (0.5–1.5 mmol/cm³) allows acrylic emulsions to meet competing demands. Over-crosslinking leads to brittle films (less than 5% elongation), while under-crosslinking causes tackiness (coefficient of friction >0.5). Advanced particle designs now achieve both high hardness (≥2H) and flexibility (≥200% elongation) by spatially controlling crosslink distribution within polymer particles.

The cold weather problem is still pretty big for many industries since standard water based coatings just won't set properly when temps drop below 5 degrees Celsius or 41 Fahrenheit. Recent improvements in surfactants and those special coalescing additives have changed things though. These new materials actually form proper films even in freezing conditions without losing grip on metals or concrete surfaces. Some tests done in the field indicate that drying times get cut down around 35 percent with these newer formulas. That makes a real difference for companies operating in places like Scandinavia, Canada, and other chilly regions where getting coatings to work has been a headache for years.

With 78% of OECD countries mandating VOC levels below 50 g/L, reformulation efforts are accelerating. According to a 2023 study by Paint.org, 62% of industrial coating manufacturers now prioritize zero-VOC acrylic emulsions. Emerging solutions include hybrid systems combining bio-based plasticizers with pH-responsive polymers to maintain durability without compromising eco-compliance.

Self-healing acrylic coatings capable of repairing micro-scratches (<2 μm) through thermal activation are nearing commercial scale. Leading manufacturers are embedding nanocapsule-based technologies into emulsion matrices, improving corrosion resistance by 40% in maritime environments. Early adopters in the automotive industry report 15% longer service intervals for coated components.

Procurement decisions hinge on three factors:

| Priority | Industry Challenge | Innovation Response |

|---|---|---|

| Cost Efficiency | Premium pricing of advanced emulsions | High-solids formulations reducing material use by 22% |

| Performance | Meeting MIL-SPEC adhesion standards | Silane-modified acrylics with 300% elasticity improvement |

| Compliance | Recyclability requirements | pH-degradable binders enabling substrate separation |

Cross-functional teams are increasingly using computational modeling to optimize these tradeoffs, with pilot projects demonstrating 18% faster compliance certification cycles compared to conventional development approaches.

Acrylic emulsions are water-based polymer dispersions used in various coatings due to their eco-friendly formulation and superior performance compared to traditional solvent-based coatings.

Water-based coatings are preferred because they significantly reduce VOC emissions by approximately 94%, comply with stricter environmental regulations, and often offer similar or superior durability and drying times compared to solvent-based products.

Acrylic emulsions are used extensively in the automotive industry because they dry quickly and help increase production efficiency. They constitute about 90% of coatings used by original equipment manufacturers.

Major challenges include maintaining consistent particle size distribution, ensuring viscosity consistency, and preventing colloidal instability in large-scale batches. Continuous flow reactors have been effective in addressing these challenges.